102 Universal Clamp Coupling – Extended Range

Universal clamp couplings with multi-band construction fit a larger range of pipe within the same nominal pipe size. Extended range/multiband clamps are designed to accommodate working characteristics of large diameter pipe. In these repair applications, there are several factors to be considered to maintain pipe integrity and return to 100% service capacity. Critical factors include: size and type of pipe, severity of damage, working pressure or service requirements, location of repair and time factor.

JCM Universal Clamp Couplings are available for emergency shipment in a variety of material combinations and sizes for specific applications. JCM Universal Clamp Couplings working pressure capabilities are directly related to the parameters of the application; for specific product recommendation and submittal, contact JCM Engineered and Technical Sales Team.

Achieve Successful Repairs through…

Heavy Duty Bolting Lug Units – Substantial high-strength, low alloy ductile iron lugs provide strength and weight to withstand high bolt torques for greatest gasket compression. Specially balanced, low profile lug design ensures efficient transfer of bolt torque energy from the lug to the gasket. Mutually supporting sliding fingers prevent distortion during tightening. Oval neck track bolts are secured in the canted ears and inhibit turning or rotation during tightening.

Addressing Increased Dynamics of Repairs – For nominal pipe sizes 10” and larger, the changing dynamics of larger circumference, pressure forces and available bolt torque requires more robust materials. JCM Extended Range Clamps 10” larger implement a larger, more massive bolting lug unit that incorporates a 3/4” bolt and thicker gauge stainless steel band.

Heavy Gauge Stainless Steel Band – Maximum thickness of stainless steel band provides full, even gasket compression on the full circumference of the pipe. For pipe sizes 10” and larger (with 3/4” bolts) clamps have a minimum material thickness of 17 gauge stainless steel.

Positive Attachment of Band to Lug – Positive attachment of the heavy stainless steel band to the lug unit is accomplished with mechanical compression of the lug and calculated weld points preventing band pull out during or after installation. Dropin,

Swing Away Bolts – Eases installation with the bolt, nut and washer remain intact, with no loose parts. Independent bolts enables simple replacement should damage occur.

Thick, Gridded Gasket – 1/4” thick gasket (sizes 3” and larger) conforms to the pipe wall and fills surface pits and voids to assist sealing on irregular pipe surfaces.

Molded In Stainless Steel Bridge Plate – blocks pinched gasket problems associated with glued-on plates, provides an even surface for ease of installation and full stainless steel encirclement protection. JCM Universal Clamp Couplings are suitable for: chemical and acid lines, air/vacuum lines, natural gas (as noted), cooling water, methane, potable and wastewater, slurry, process and other line contents. Gasket materials readily available include: SBR, Buna-N, EPDM, Hypalon and others upon request. Provide content information to JCM representatives for application recommendation. Advise JCM representatives of any possible line solids or abrasives within the line content.

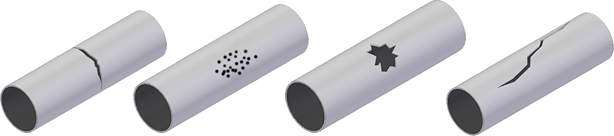

Suitable for these types of damage:

Applications

Repair Temporary/Permanent:

- Breaks

- Cracks

- Splits

- Holes

- Corroded Areas, Pin Holes

- Connection of Plain End Pipe